Quality

Since the foundation of the company, the quality of the manufactured and the satisfaction of our customers have been our top priorities.

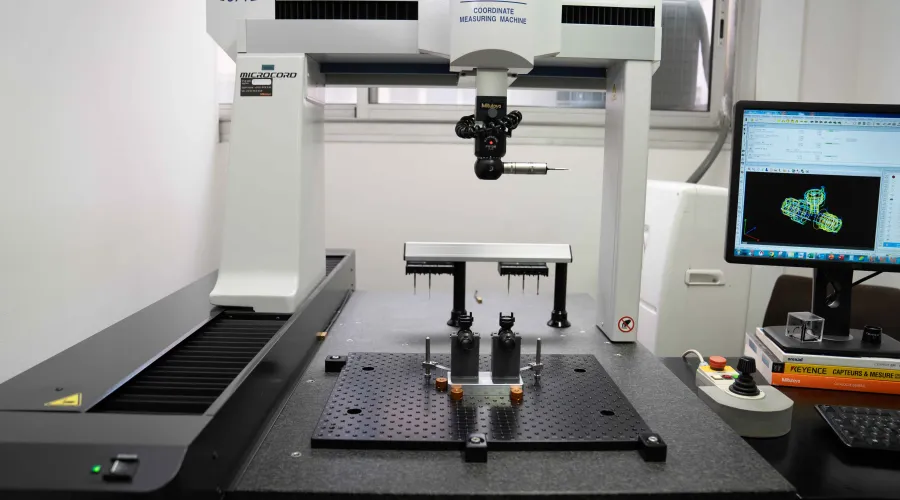

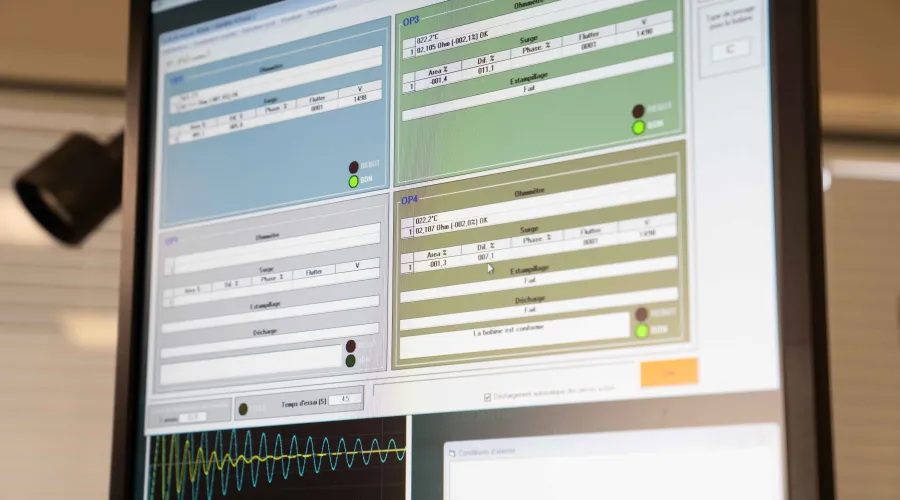

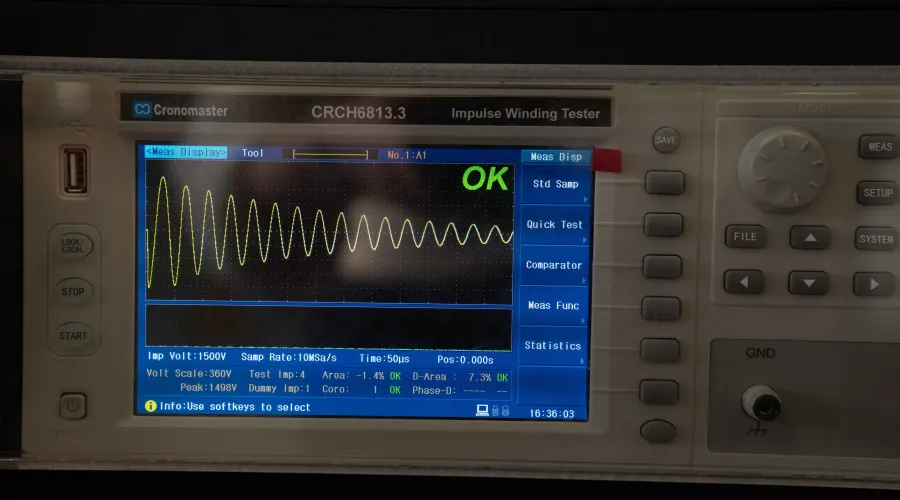

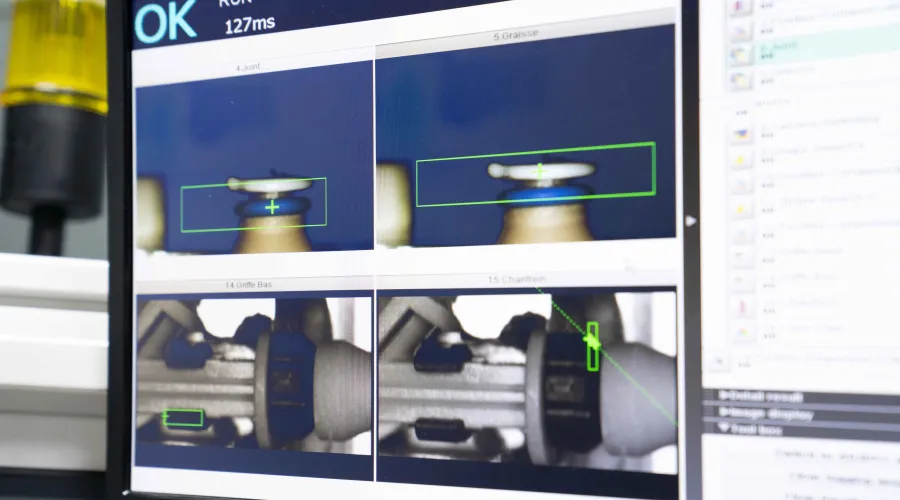

Our work methodologies and the rigor of our organization combined with our means of production permit us to get closer to 0 defects (PPM).

PG Plastic was one of the first companies in the sector to obtain ISO9002 certification in 1992.

To date, we are certified by AFNOR, following the ISO9001 and IATF16949 standards.

Environment

We have initiated a process of continuous improvement of our performances and our system is based on several axes:

- 100% of the electrical energy consumed to power our site is of renewable origin.

- Our cooling circuit is closed loop.

- 90% of the lighting in the premises is LED.

We can integrate recycled and recyclable materials, eco-friendly processes into our plastic injection molding solutions, providing our customers with options that respect the environment without compromising the quality of our products.

We adopt practices aimed at minimizing waste and optimizing the use of energies.

From design to production, we implement initiatives aimed at reducing our environmental impact, thus contributing to building a more sustainable future.